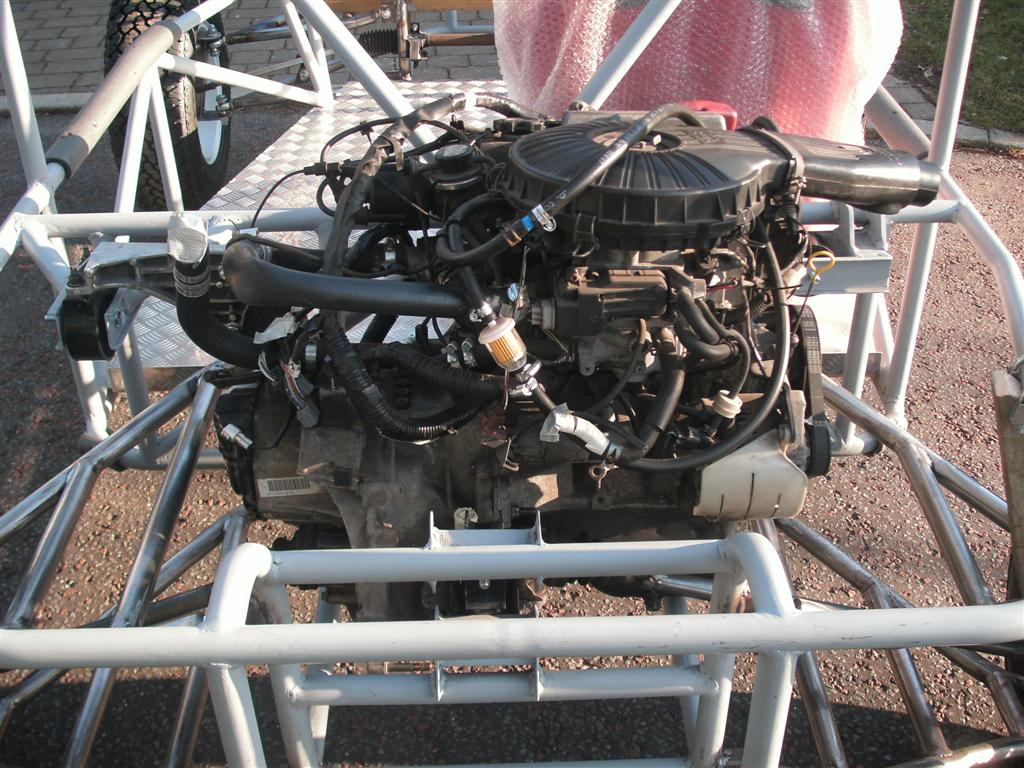

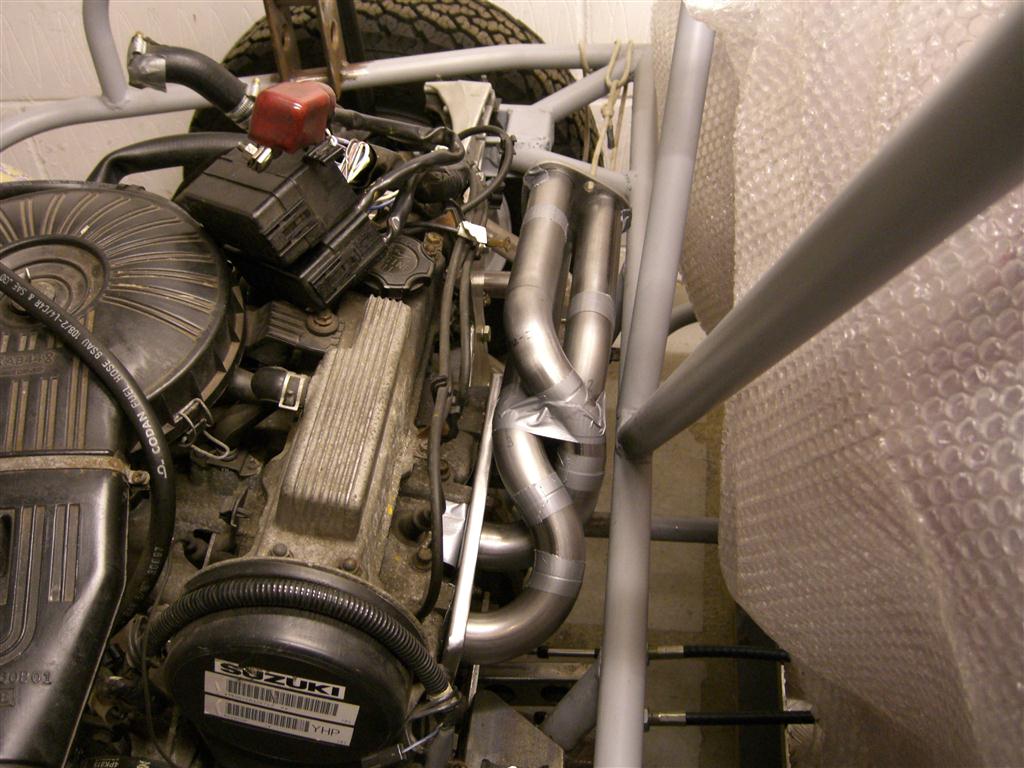

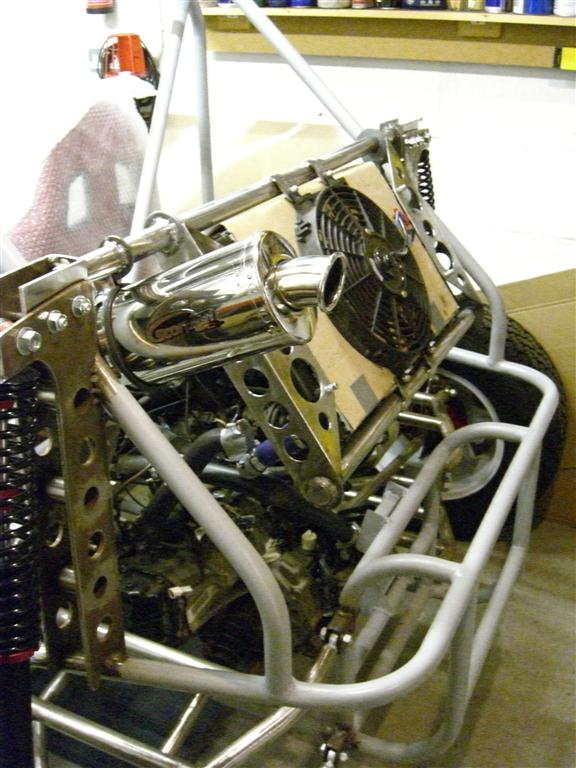

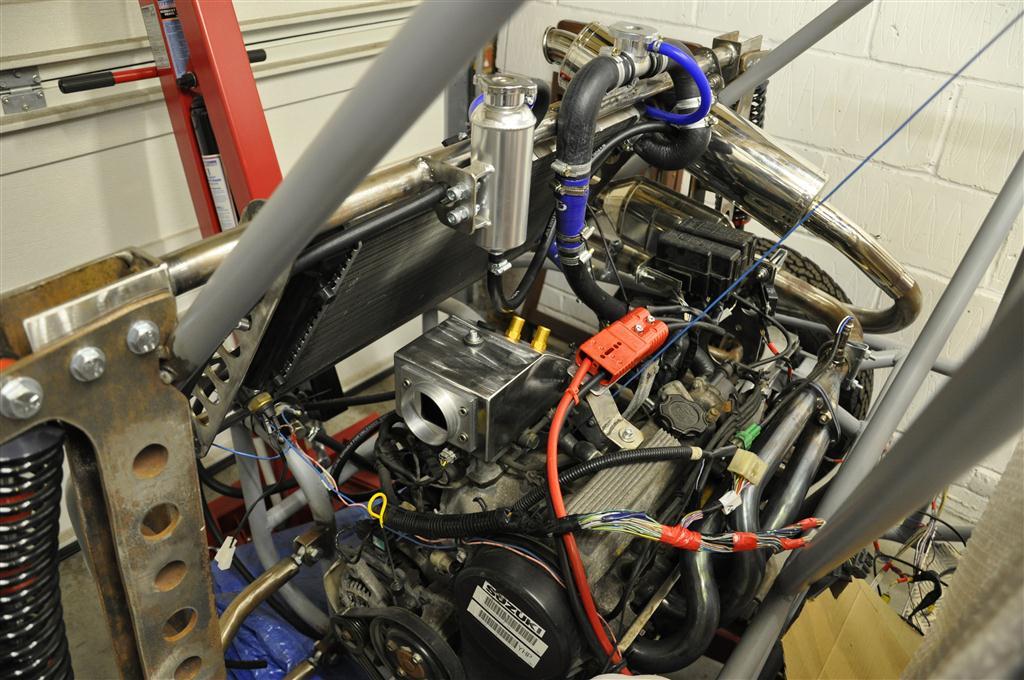

Hi everyone, New to the forum but did say I would post some photos of the buggy build so far, so here goes!!, I still have a long way to go but the project is going well so far, without too many major issues (those will come when I try to get it registered for road use). The buggy has been designed by myself (and a good bit of CAD software) and is powered by a suzuki swift engine and box.

Anyway I have a LOT of build pics over on my build site but here are a few to get you started :-

Day 1 280 feet of 1.25" (32mm if your in the UK) 2mm wall ERW tube - it dosent look much once its chopped up!

Majority of chassis parts bent to correct angle with the homemade tube bender:-

Start of the lower chassis section:-

Chassis main roll over bar and rear cage:-

Chassis midsection and upper roll cage:-

Chassis Upper section in place - starting to look right :-

chassis with diagonals and engine mounts in place (and a bit of undercoat):-

Here is a quick video:-

YouTube - Ultralite Buggy Construction Video No. 1

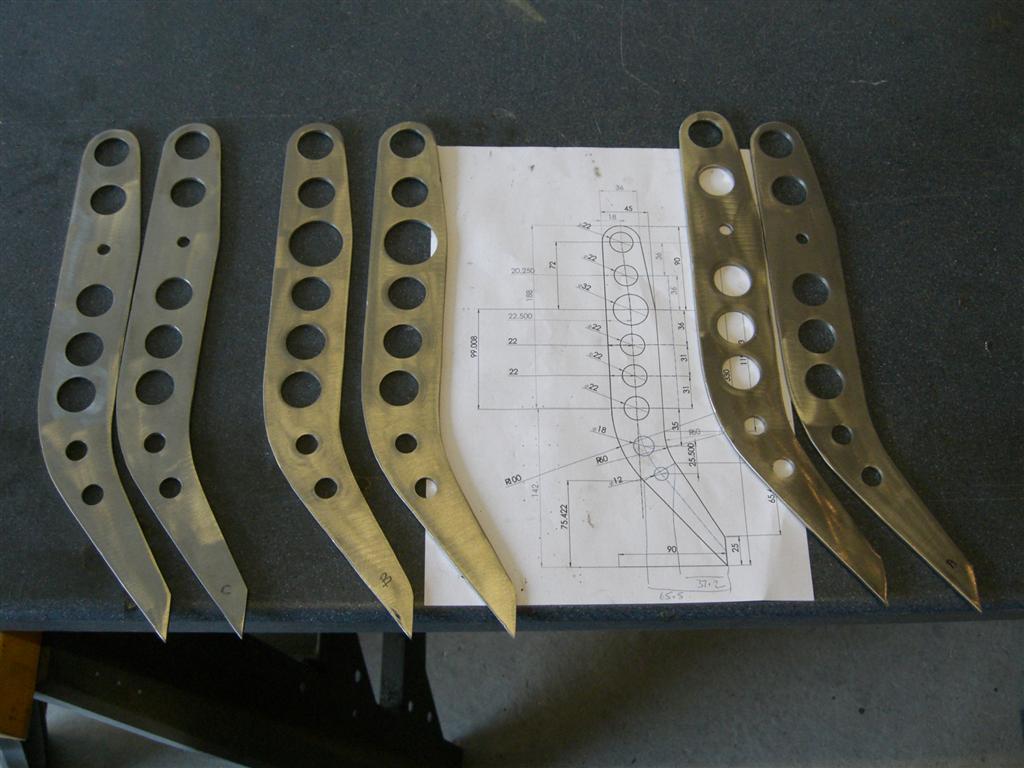

At it with the pipe bender again these 8 bits are the sides of the suspension A arms :-

The jig to ensure all the arms are the same and repeatable :-

finished arm with a single rose joint in:-

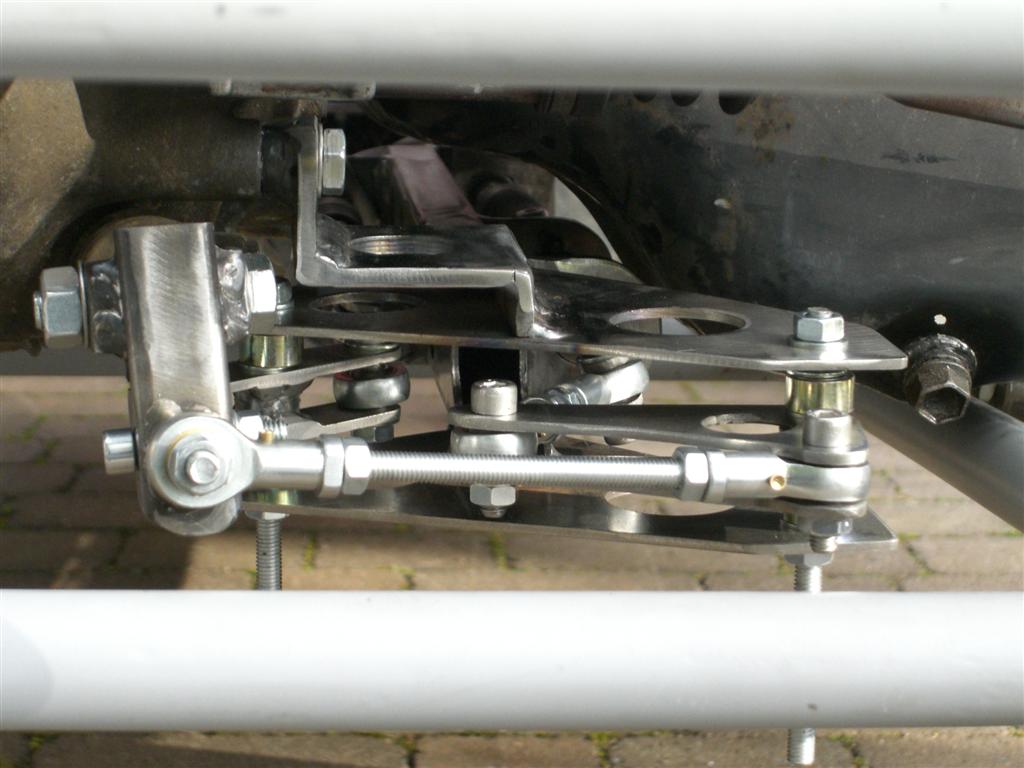

Both rear arms for one side mounted to the hub:-

arms and hub hung in place at the back of the chassis:-

First arm mounted correctly :-

Final two rear suspension wishbones / A arms they need final trimming to length (note black lines on tube ends:

A couple of shots of the rear suspension in place:

and another:

And finaly a shot of the chassis with rear arms in place and new alloy floor:

View of rear suspension showing shock location and new hub top mount (lower mount finished and now in primer-

View from rear showing all suspension and shocks (shock upper mounting hoops not done yet)

Side view with one of the new rims bolted on

Rear view with rim

the 4 front arms built (but not finished quite yet:

And the front verticals in place ready for the suspension:

Been busy again, rough fitted at the moment but you get the idea

And another shot of the front suspension -

Picked up the tyres (General Grabber AT2 225/70/15), so I thought I'd put the rear suspension back together (as its easier to roll it out) as you can see its a tight fit in the garage now [smilie=ecstatic.gi:

Well I wanted to get the buggy to a rolling chassis stage before the end of the year - and I made it!! - with only a few hours to spare (Finished new years eve 18:00 (2010) - in the dark!!) didnt get much chance to photo anything at the time apart from the tight fit in the garage!!

See what I mean....

The next morning managed to take a few more shots here's a few:-

Still loads to do, like add the double shear to the front hub adaptors, sort out the rear shock mounts after checking the movement on the drive shafts etc...etc...etc...

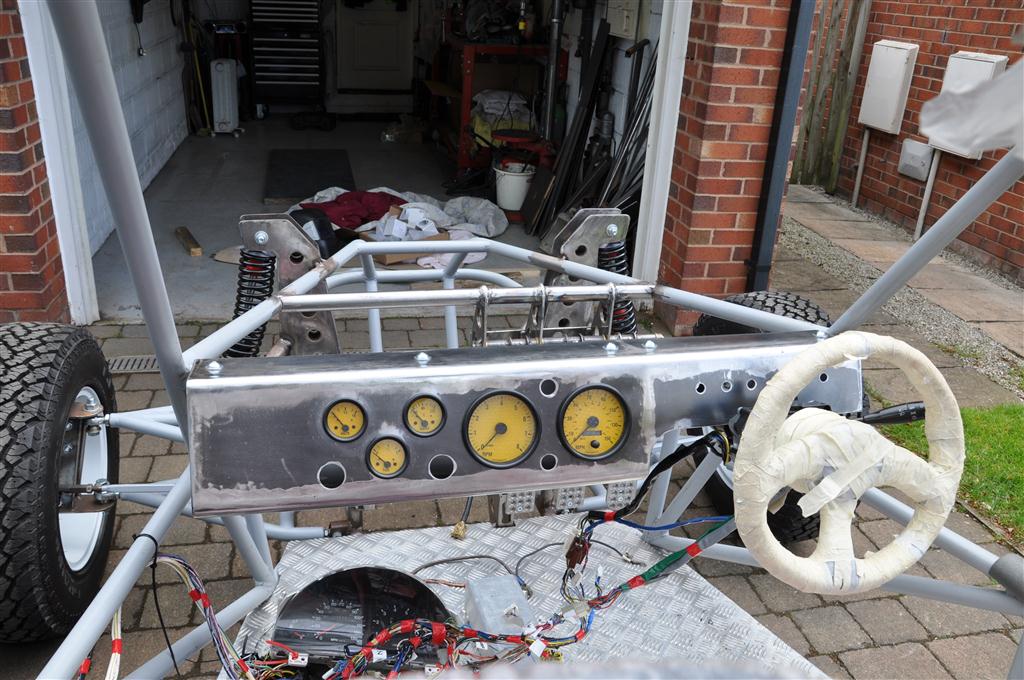

Its a nice sunny day so thought I would take a few progress shots,

And then I put her back in the garage (taken the following day after I put the proper temp driveshafts in!! (the ones in the pics above were only to get the correct length!!

And here is another construction video:-

YouTube - Ultralite Buggy Construction Video No. 2

And yes I know its called construction video no. 2 and I say its the third video... but the first vid i did on youtube was of the engine running on the stand I built for it - search for videos from TheBuggyBuilder and youll find it - thats if your really bored with nothing better to do that is!!

rear suspension mounts prior to fitting to the chassis:-

And a few once fitted (and a second one built and fitted) also shows new seat mounts and steering column mount (first of two)

front suspension is now sorted (apart from the correct spring rates which is why its so low on the pic

Here ya go:-

Still loads to do, working on fitting the MR2 gear change assembly and cables next I think then pedal assembly!!

I have been busy in the garage recently building (and then scrapping and re-building) the gear shift assembly. Its using a Toyota MR2 Gear change assembly with MR2 Turbo Cables (soon to changed for custom units attached to a fabricated shifter assembly at the rear of the vehicle, so here are a few pics;

Alloy section used to house handbrake and gear shift assembly, cables atttached but layed onto to measure up!

Cut outs done for mounting cables through

Working version of the selector mechanism bare

Mechanism with push rods and cranks fitted (extended threaded rod to be swapped out)

Fitted in position at the back of the buggy! (Again the extended threaded rod is to be swapped out with correct length bolts)

A lot of work went into getting this correct, it was surprising just how much work was needed just to find out how big the cross gate crank needed to be! Anyway it works like a dream now, just enough movement across the gate and a good notchy click as it goes into each gear, overall I'm very happy

I am now working on the pedal assembly which is a hung assembly - as a floor mounted one to me didnt feel as good - anyway its another scratch build job (should'nt take as long as the gear change )

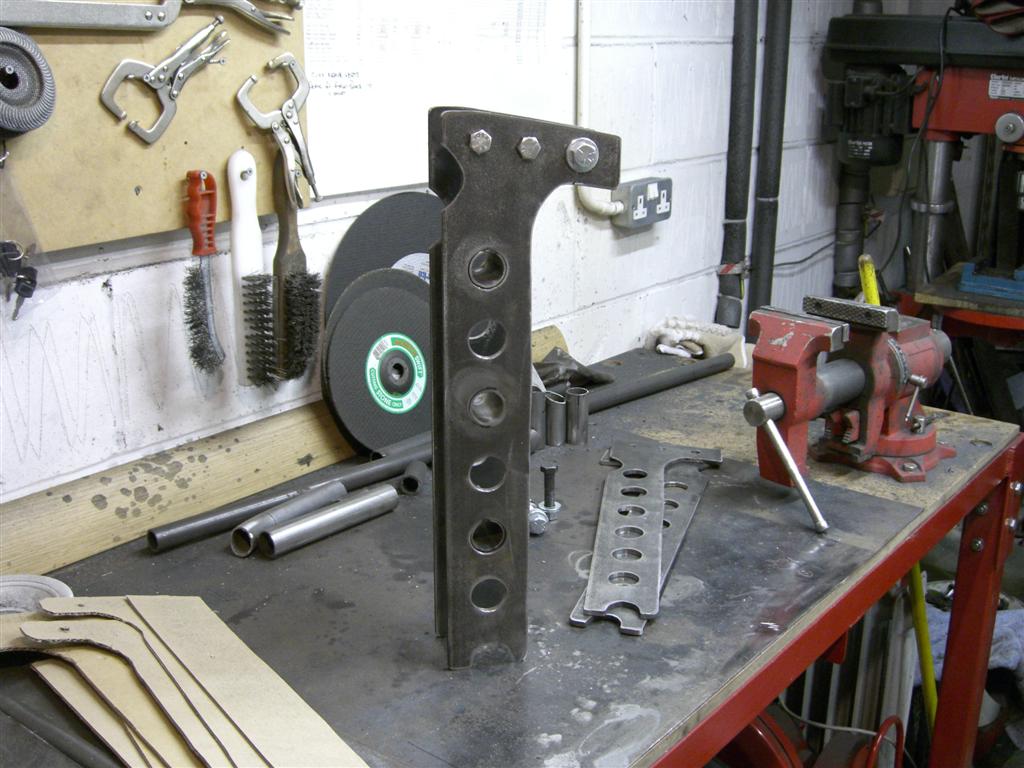

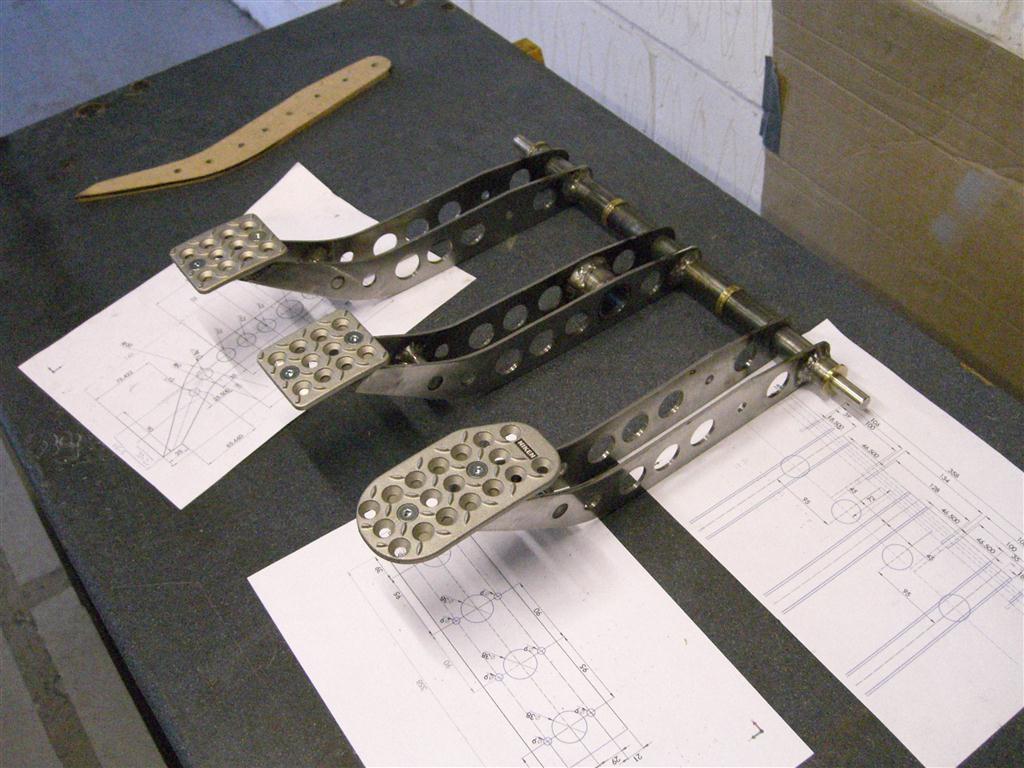

Got the pedal assembly designed and started cutting out the pedals, so here are a few progress shots:

Blanks rough cut-

Blanks drilled and cleaned up:

And finally welded together;

Just need to weld the spindle tubes into the top of each and add the foot pedal mount at the bottom of each now and crack on with rest of the assembly

Finished Pedals

And the mounting for the pedals

more work on the pedal assembly had to scrap the backplate i originally did as the two master cylinders for the brake were set at what I thought was the correct width but after assembly and testing the balance bar kept locking / binding so off came the plate and a new one made and everything welded back together.

This is what it looks like now with spring return bar and pedal stop in place-

And finally hung in the buggy - its a snug fit

....just teasing

....just teasing